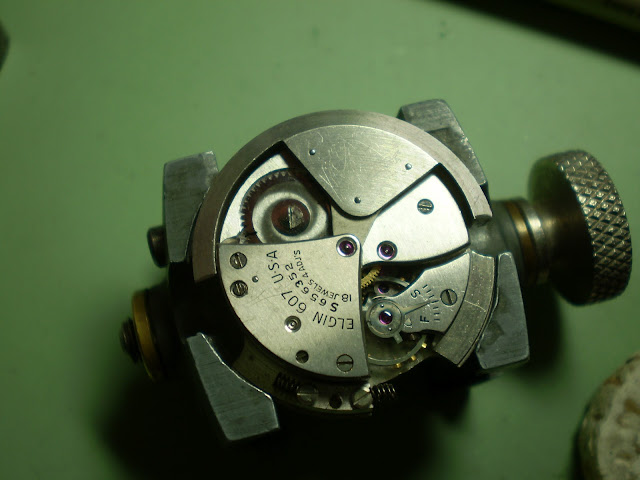

Compared to manual-wind watches, automatics of that era were just plain chunky. Here's an Elgin 607 Bumper next to an Elgin 687, one of the 8/0 series of manual wind movement. Note just how much thicker the 607 is.

Buren tried to address this with their Microrotor movements. These are found in Hamilton's Thin-o-matic series. Their approach involved putting the time train and the self-winding works on the same level. The winding is accomplished by a small rotor rather than a movement-sized rotor. You can see it on the left in this picture.

Some of these movement used an off-center center wheel for more space, which drives the minute hand indirectly. One complaint about these micro rotor movements is that the smaller rotor doesn't always fully wind the mainspring, especially when the watch is older or in need of service.

This is likely why current automatics use a full sized rotor. Of course in these days of big watches, the thickness of the movement is no longer an issue. Most watches dwarf the movements they contain!

Eight years after Elgin abandoned the 607/618 'Bumper' automatics, they introduced a new series of American-designed and -built selfwinding movements, the Durabalance Automatics.

In designing these, it seems as if Elgin started with a blank sheet of paper, and did not follow the conventions of other automatics. These movements were technologically advanced and cleverly designed, incorporating several advances.

First, the Durabalance, a mass-produced free-sprung balance with an ingenious method approach to regulating the rate. As I described in an earlier post, in the Durabalance a pair of weights (d) hooked over the spiral balance arms (b) are connected via a flat leaf spring (c). Moving the spring causes the weights to move along the balance arms, increasing or decreasing moment of inertia and thus decreasing or increasing the rate.

Brilliant idea, but in practice the tolerances are loose enough that the poise of the balance is not always right because the weights don't move in exact coordination. Also, regulating the watch requires you to stop the balance and hold it while you move the spring one way or another.

Like the Buren microrotor, the 760/761 series put the selfwinding works on the same level as the time train, making the movement itself much thinner. Unlike the Buren, however, the 760/761 used a full-sized rotor. Whereas other automatics have a bidirectional clutch in the selfwinding works, the 760/761 put the clutch in the rotor hub. The clutch itself was unique, incorporating 6 round, flat jewels that transfer the motion of the rotor to the selfwinding works via gears A and B.

The jewels themselves are housed in asymmetrical openings in Driving Gear A and Assembly B. Looking at A, when the rotor is spinning counterclockwise, each jewel is pushed to the narrow end of the slot, where it wedges in and transfers the motion of the rotor hub to the driving gear. When the rotor turns clockwise, the jewel is pushed to the larger end of the slot, where it spins, allowing the gear to freewheel. Assembly B is set up in the opposite direction, so that clockwise motion drives Assembly B and its associated gear while Gear A freewheels

Gears A and B can be seen in this picture

This also shows the clamp and clamp screw which fix the rotor to the rotor post. Gears A and B mesh with different parts of the autowind mechanism

R is the rotor post

1 is the First Autowind Wheel

2 is the Second Autowind Wheel

3 is the Rotor Idler Pinion

4 is the Click

Gear A meshes with Rotor Idler Pinion 3, which in turn meshes with First Autowind Wheel 1

Gear B meshes directly with First Autowind Wheel 1

First Autowind Wheel 1 drives Second Autowind Wheel 2.

We'll get to what Second Autowind Wheel 2 meshes with later.

The Click (4) works on First Autowind Wheel 1, rather than on the ratchet wheel. Where's the ratchet wheel, you may be asking. We'll also get to that later!

Here's how it works.

When the rotor turns clockwise, Gear B is locked, so it turns as well.

It turns First Autowind Wheel 1, driving Second Autowind Wheel 2

The Rotor Idler Pinion spins clockwise, while Gear A of the rotor freewheels.

When the Rotor turns counterclockwise, Gear A is locked and turns with the rotor.

Gear A turns Rotor Idler Pinion 3 clockwise, which turns First Autowind Wheel 1 counterclockwise, driving Second Autowind Wheel 2.

Gear B freewheels.

So, how does this wind the mainspring? For that, we have to look at the dial side.

The Pinion of the Second Autowind Wheel drives the Ratchet Idler Wheel A, which in turn drives the Ratchet Wheel B. That's right - the ratchet wheel is on the DIAL SIDE!

This is to accomodate the winding and setting mechanism, which uses a rocker plate instead of clutch. With the Rocker Plate in winding mode, the Winding and Setting Wheel C turns the winding wheel D, turning the Ratchet Wheel B and winding the watch.

Remember how the Click works on the First Autowind Wheel? It's the only thing holding the ratchet wheel. The full force of the wound mainspring is on the Ratchet idler wheel, the Second Autowind Wheel, and the First Autowind Wheel. BTW, if all is working properly, hand winding the watch spins the rotor.

To set the time, pulling up the stem causes Setting Lever A to push the Rocker plate so that Setting Wheel B meshes with Hand Driver Wheel C.

The Hand Driver Wheel is frictioned onto the off-center Center Wheel, much like a Cannon Pinion in an ordinary watch. It drives the Minute Wheel, which in turn drives both the Hour Wheel and the Cannon Pinion, which simply slips down over a post in the center of the movement.

The Train, despite its off-center Center Wheel, is fairly standard.

Here you can see the Escape, Fourth, and Center Wheels. The Third Wheel is obscured by the Center Bridge Plate, which carries the Rotor Post as well as the Rotor Idler Pinion Post.

With the other wheels removed it's easier to see the Third Wheel.

With the Center Bridge Plate removed, you can see the Sweep Second Pinion, engaging the Third Wheel.

The sweep second hand is driven indirectly. Often sweep second hands driven this way will skip or jump. This is because wheel teeth are designed to be driven smoothly by pinion teeth, but not to drive pinion teeth, so the pinion moves in a jerky fashion.

To cure this, there is a bronze washer underneath the pinion gear, which pushes the pinion up so that the top of the pinion contacts the bottom of the Center Bridge Plate, providing just enough friction to keep the pinion teeth properly meshed with the Third Wheel teeth.

It's effective - of all my 760s and 761s, only one has had 'jerky' second hand motion. I suspect the washer is missing or needs to be bent to provide more tension.

So, with all this, how does the Durabalance automatic stack up, thickness-wise? Here it is compared to the 687 and 607 from way up above. As you can see, it's much thinner than the 607, and pretty close to the 687!

And there you have it - the Durabalance Automatic, one of the only automatic watch movements completely designed and built in America.

Now, about the 'Lemon' part. As innovative and unique as these are, there are several design flaws that plague them, and which anyone hoping to collect these needs to be aware of. I've bought at least 11 of these, either as watches or as movements. Only 4 were in running order when I got them, and I've managed to get 2 others working. Below are the broken parts from the other movements.

Going clockwise from the upper left:

A. Lower Center Wheel jewel popped out - it's the little 'Cherry Life Saver' by the arrow point.

B. Center Post popped out. To be fair, this movement looked like it had been run over by a tiny truck, right down to a tiny tire track across the dial.

C. Loose Rotor Hub. I've had three of these. If you look at the rim of the rotor, you can see where it rubbed on the plate.

D. Broken Minute Wheel Clamp. The little arm at the top broke off of the little piece at the bottom. According to more several professionals, this is a frequent problem.

E. Second Autowind Wheel. This piece is one of the two most frequent problems. Among these 4 wheels, 2 have broken lower pivots, 1 has missing teeth on the pinion, and 1 has a broken wheel. Remember that odd click arrangement? I suspect this is the weak link in that particular chain with all the force on that poor little pivot.

F. Missing Teeth on Winding Wheel on Rocker Plate. In my sample, this happens as often as 2nd Autowind Wheel issues. I wouldn't be surprised if there was a link between that and the 2nd Autowind Wheel weakness, and perhaps breaking one leads to breaking the other.

E. Loose Rotor Post. On these two Center Bridge Plates, one has a loose rotor post, and the other has had a repair attempted.

So many of these particular parts have failed that spares are very hard to come by.

The Durabalance Automatic, then, is a fantastically innovative movement, very different from other automatics, with a number of novel features, but with at least 3 Achilles Heels. Any collector is well advised to purchase only fully working examples, and perhaps a couple parts movements as well. And have it professionally serviced!

UPDATE: After Brian's comment, I wanted to add a note to collectors and potential collectors about hand winding these watches - BE GENTLE!!

I believe that hand winding these watches is supposed to spin the rotor, which puts a lot of strain on the teeth of the rocker plate wheel (F), as well as on the 2nd Autowind wheel (E). This may be what causes their frequent failure. So, wind carefully, and don't wind much. Just start it and then depend on the autowinding.